It’s been a while since we have posted information pertaining to the orientation of diamond core for collection of structural geological data. At the risk of boring people, I’ll reiterate some basic statements about the value of using correctly oriented diamond core. You can skip this and go to the next section if you wish, although ongoing experience seems that many people still aren’t getting the basic messages regarding core orientation.

From a geological perspective, the use of diamond drill core is paramount in hard-rock exploration and mining. It provides invaluable information for prospect evaluation, Mineral Resource and Ore Reserve estimation and general geological understanding. With few exceptions, the mineral occurrences drilled have an architecture dictated by structure. Oriented diamond drill core is therefore critical to providing information on the structural controls to mineralisation, which in turn adds confidence to geological and Resource/Reserve models.

The process of oriented core collection should not take value from the project through unnecessary expense or loss of productivity. To this end, oriented diamond core should fulfil the following objectives:

- there should be no interruption of the drilling cycle and productivity should not be compromised

- the orientation method must be cost-effective

- drillers and geologists should possess a full understanding of the desired objectives and meet them through regular and accurate orientations

- core orientation methods may need changing due to ground conditions (and possibly driller experience)

- back-up systems have to be in place if a particular method or orientation tool fails

- a permanent record of the method used needs to be kept

- if not sampled, oriented core should be available for future interrogation and half-core should preserve the orientation mark and line.

If you want more information on core orientation, and the use and abuse of oriented core, check our previous blog posts Drill core orientation - An Inconvenient Truth Part 1, Part 2 and Part 3.

Alternatively, wait until AusIMM’s Monograph 30 on best practice in the mining and exploration industry comes out later this year. This will include a contribution by Orefind on oriented core.

The latest offering

Late last year I visited the workshop of 2iC Australia in Perth. 2iC’s latest offering in the field of core orientation is their new Ezy-Ori(TM) Orientation System (Figures 1, 2, 3 and 4), which they describe as ‘Back End, Audit-able, Verifiable, Automatic’. Note that the images in this blog are Copyright 2iC Australia Pty Ltd and have been supplied by 2iC management.

The term ‘Back End’ may seem a bit contrary to a device that is supposed to give good results but it refers to the location of the orientation tool. 2iC’s other well know tool, the Ezy-Mark(TM), is mounted at the front end of the inner tube and takes the orientation of the core stub at the bottom of the hole prior to drilling. The new Ezy-Ori(TM) tool is similar to Ezy-Mark(TM) in that it is a mechanical device that uses the same system of three indicator balls (Figure 2) to determine the bottom side of the hole by falling due to gravity. However, the Ezy-Ori(TM) instrument mounts on the back end of the inner tube (Figure 3). One advantage of this is that the tool can be lowered at much higher than normal speeds into the water table than normal orientation tools.

Figure 1. The Ezy-Ori kit

Figure 2. View of the assembled Ezy-Ori(TM) system to show the white balls, which are locked after falling under gravity. As with the Ezy-Mark(TM) system, the alignment of all three balls as shown indicates a high confidence orientation.

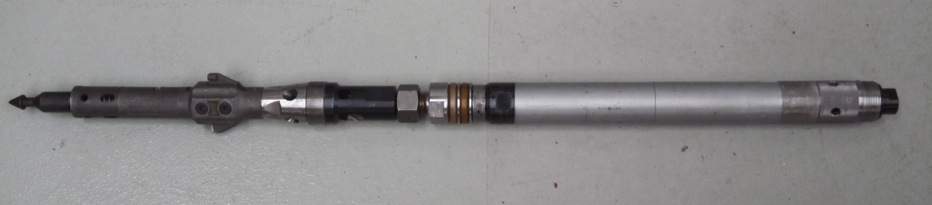

Figure 3. Assembled Ezy-Ori(TM) tool. The section containing the three balls is screwed into the right hand end.

Figure 4. Using the magnetic device to release the previously aligned balls (top) such that they are scattered and free-moving (bottom).

How it works

Before beginning drilling the balls in the device are ‘scattered’ using a small magnetic tool (Figure 4). As with Ezy-Mark(TM), this allows the orientation balls to run freely in their housing during the rotational aspect of drilling. At the end of a drill run, the rotation of the rods is stopped and the ball locking mechanism is delayed to allow the orientation balls to settle on the bottom side of the hole. It is essential that the drill bit is allowed to run out momentarily without downward force so as to reduce or eliminate any built-up rotation torque within the drill string. After drilling has stopped, a waiting period of 60 seconds is required before breaking the core and retrieval, allowing the orientation balls to settle and lock correctly. The locking mechanism is activated by a magnet retracting back from the orientation section of the tool after the rods have stopped spinning.

Drilling-induced potential for error

As noted above, it is essential that the drill bit is allowed to run out briefly to avoid problems related to rotation torque within the drill string. Failure to eliminate rotational twist in the drill string at the end of the core run may result in the drill string and core barrel rotating a couple of degrees as the core barrel is lifted off the bottom of the hole, which can result in an inaccurate orientation reading. It will be obvious that the breaking of core should not involve any rotation to assist with breakage.

Another avenue for error is that of ‘double tagging’, a procedure commonly used to contact the bottom of the drill hole after the drill bit has been lifted off the bottom of the hole and the core broken off the bottom of the drill hole. This can move the core rotationally in the core lifter and core lifter case causing an inaccurate orientation reading. This procedure affects all backend orientation devices as they rely on orientating the core tube after each drill run. The Ezy Mark(TM) by contrast, takes an orientation of the core stub (not the tube) before drilling commences. Subsequent movement of the core inside the tube will not affect the quality of the orientation.

Will Ezy-Ori replace Ezy-Mark?

On speaking with the Operations Manager for 2iC, Chris Holliday, it seems the general consensus is that Ezy-Ori

(TM) is more likely to replace back end electronic orientation devices. In addition to the various positive attributes championed by the respective companies, some people simply feel more comfortable with mechanical devices. With respect to 2iC’s other popular orientation system, Ezy-Mark(TM), there will always be a place for it. This is especially true when an audit trail is required.

For more information, contact 2iC Australia at the following:

www.2icaustralia.com

Phone: + 61 8 6310 3888

Fax: + 61 8 9331 3288