The greatest enemy of knowledge is not ignorance; it is the illusion of knowledge.

- Daniel J. Boorstin (American historian)

In the mining industry, we are facing resource downgrades of up to 90% (Financial Post, 2016), even with the use of modern geological modelling software such as Leapfrog. Why is this the case, especially when the makers of Leapfrog claim on their homepage that you can ‘reduce geological risk’ by using their software? But maybe it’s not the fault of the software; instead, perhaps geologists cannot model deposits effectively—but why is this so?

I discuss the fundamental reason for why I believe this is occurring, some 14 years after Leapfrog software was released to the mining industry.

So what is the fundamental problem?

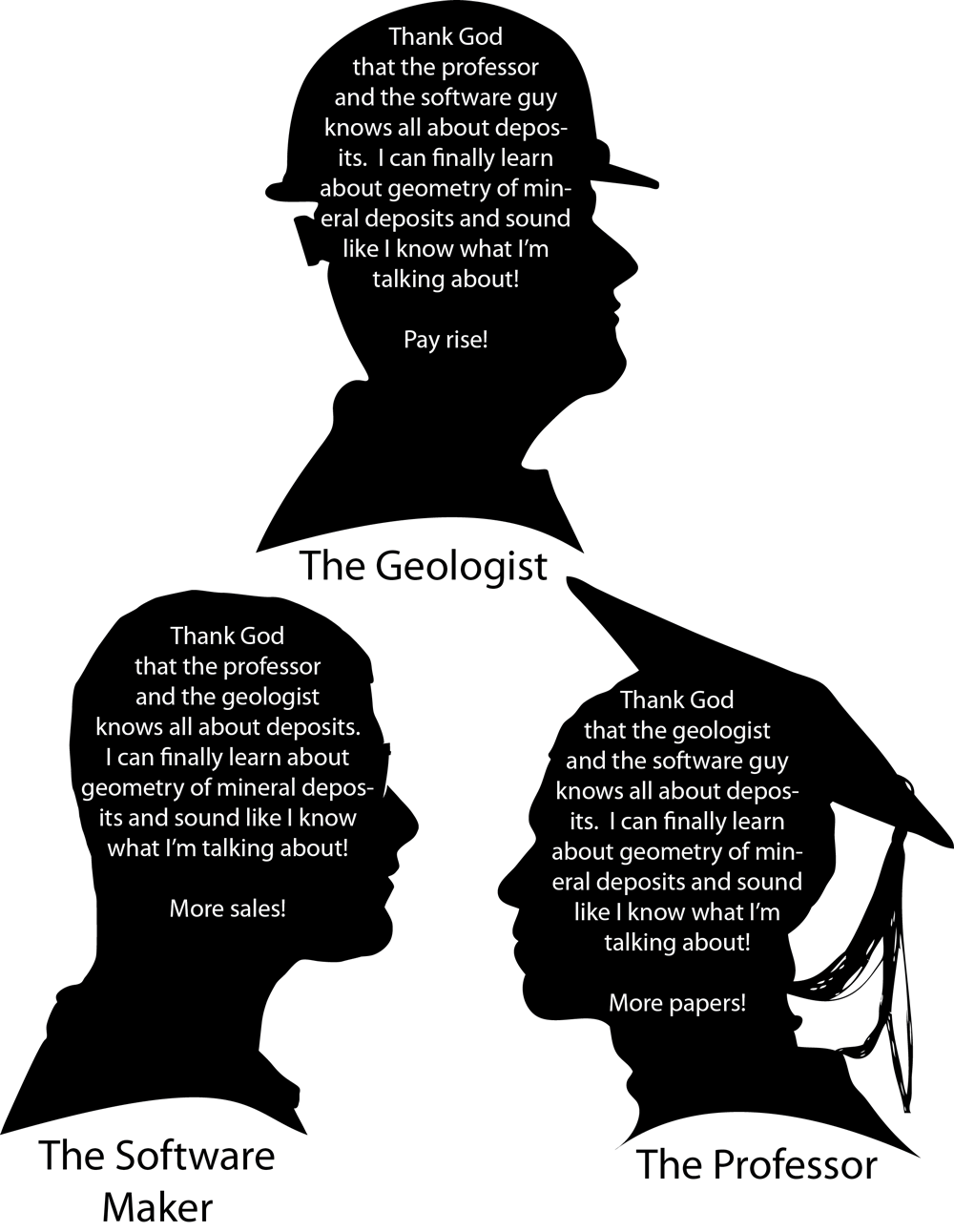

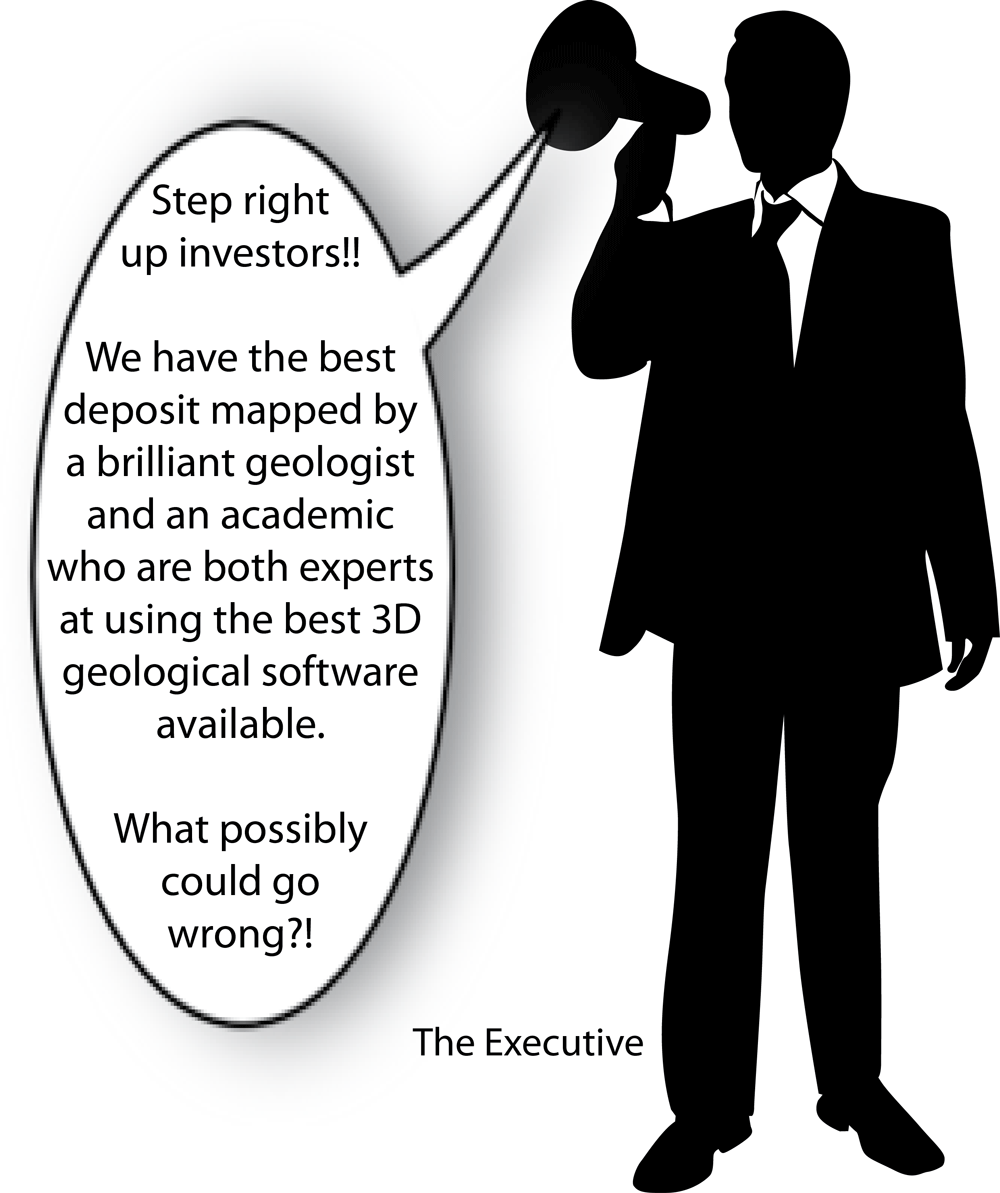

The fundamental problem is widespread ignorance of how structural geological architecture plays a key role in the geometry of mineralisation. This ignorance is pervasive in the mining industry, not only affecting geologists working in the industry but also their university lecturers and professors—well-respected academic economic geologists. The software developer assumes their users in the industry know what they’re doing, when that’s not the case. Ironically, geologists and academics both view the software as an answer to their prayers and assume the software company knows what it’s doing and is designing features that will provide answers (Figure 1), which may not be the case. The mining and exploration company executives rely on these professionals to help deliver the ultimate benefit to the shareholder, yet are completely unaware of the reality of ignorance that pervades the industry (Figure 2).

Although structural geological ignorance is pervasive in the industry, it is the illusion of knowledge that each party has of the other, which is the main issue that dogs the mining industry.

In this post I explain how I think the mining industry found itself in this state. A more detailed assessment can be found at Cowan (2017).

Figure 1: The assumptions of the geologist, the academic geologist and the software maker. No one seems to be in charge.

Figure 1: The assumptions of the geologist, the academic geologist and the software maker. No one seems to be in charge.

Figure 2. The executive promoter, a true believer.

Figure 2. The executive promoter, a true believer. ‘Geological modelling’ or geological doodling?

The reason why geologists don’t know how to model mineralisation patterns is because the only education they have about geological modelling comes from the software makers, who teach geologists how to press which buttons and what methods should be used for particular modelling problems. However, they do not teach geologists anything about the geological controls on mineralisation—about how mineralisation patterns are the product of structural control, and the implications of such control on mineralisation geometry—because the software makers simply do not have that knowledge.

Without this crucial knowledge, software instructors cannot effectively tell geologists WHY they should use a particular modelling method or use geological reasoning to explain their choice. In essence, ‘geological modelling’ is not ‘modelling’ as a physicist or engineer would understand it where a model is created to obey certain physical state. What the mining industry refers to as ‘geological model’ is nothing more than a ‘3D sketch’, which is not linked to any physical reality. How could this happen?

Industry ‘best practice’ that isn’t really best practice

This is because of the long-standing industry ‘best practice’ is to not seriously consider geological controls in the geological modelling process, and to largely ignore the role of structural architecture. Ask any resource modeller or geostatistician—they likely have very little idea about how the 3D shape they’re working with has anything to do with structural controls, and can give you no logical explanation for it. Yet this is considered by most to be ‘industry best practice’. The geologist and the software maker have the same (ignorant) state of knowledge and just create shapes with little geological thought behind the workflows they use. Yes, they can go through the steps and create something that appears reasonable to the uninformed, but there is often no geological meaning or logic to the process they choose to use. Geological logic does not come into the modelling process, so they are under the illusion that they’re doing the right thing, yet they don’t know if they actually are because they don’t know what they don’t know. Under the guidance of the software makers, geologists are simply going through shape-generating steps, often devoid of geological reasoning; neither the geologists nor the software maker can judge what is right or wrong—a classic blind-leading-the-blind scenario.

Leapfrog is hardly ‘disruptive’ to the mining industry

Although Leapfrog and other implicit modelling software can be viewed as being ‘disruptive’ from a technological standpoint (Christensen, 1997), such software is certainly not disrupting the economics of the mining industry—instead, it may be making the situation worse because costly mistakes can occur much faster with implicit modelling. So far, the widespread uptake of Leapfrog has not stopped costly resource downgrades and the creation of unrealistic and bad geological models that will have long-lasting economic ramifications (many examples of which can be found in

NI43-101 technical reports). In practice, we have not moved on from where we were before the invention of Leapfrog. I find this truly sad, as my vision was that Leapfrog could change this situation, be truly disruptive; however, without meaningful structural understanding by geological modellers and software makers, such change is unlikely to happen any time soon.

As part of my contribution to shifting the industry, I trained my Leapfrog Mining users in the structural geological architecture of their deposit first—I viewed this as essential prerequisite knowledge for any geological modelling process. The greatest risk of getting the geological interpretation incorrect results from not being able to read the structural patterns that control the deposit from the raw data. An introductory ‘one-size-fits-all’ software training is only relevant for the specific training material that is provided by the software maker. Unfortunately assessing and modelling real datasets is beyond the scope of many software trainers as many are unfamiliar with structural geology and therefore are unable to see critical controlling geometries from real data. A competent trainer should be able to tell you the structural control of your mineral deposit within 30 mins of loading the drill hole assay data (note: not structural data, but assay data. This technique which can be used on all deposits is explained in Cowan (2014)). Without this initial analysis, there is no point in going through the process of modelling because things can rapidly go downhill from that point onward.

Geologists are never taught the essential skills in university

One major reason why geologists don’t know how to model effectively is that they’ve never been taught anything about the 3D geometry of mineral deposits at university. The only time they learn about this topic is on the job, often at a geological modelling training session run by a software maker whose expertise or experience is not geology!

Let me use an allegory to explain this crazy situation, which, for some reason, doesn’t seem to worry too many people in the mining industry.

Imagine you’re studying to become a physician and you’re taking a course on how to interpret CAT scans. Your instructor is the computer programmer who built the CAT scanning software—they know a lot about programming but nothing about human anatomy, yet they’re going to be teaching you. How effective do you think this lesson would be and would you be dismayed that the instructor is ignorant about human anatomy? In another scenario, consider that you’re a budding pianist and you want to learn how to become a great piano player. Who would you get advice from? A piano teacher who is an accomplished piano player, or a piano maker who is expert at building pianos? I know who I’d prefer to learn from!

Geologists routinely get geological modelling advice, but not from those who actually have experience at viewing lots of drilling data and can identify key structural geological controls. Instead, they go to the software maker who knows how to operate the software, but cannot explain the geological logic of what they should be doing and how they should be doing it, based on the structural anatomy of the deposit. Do you think this learning approach will ‘reduce geological risk’?

Institutional illusion of knowledge

You would think that geologists get exposure to geological modelling at university, but this certainly isn’t the case. Plenty of academics teach conceptual economic geology, but nearly all economic geologists have no idea about what controls the geometry of mineral deposits—the very issue that is at the heart of mineral exploration and resource estimation.

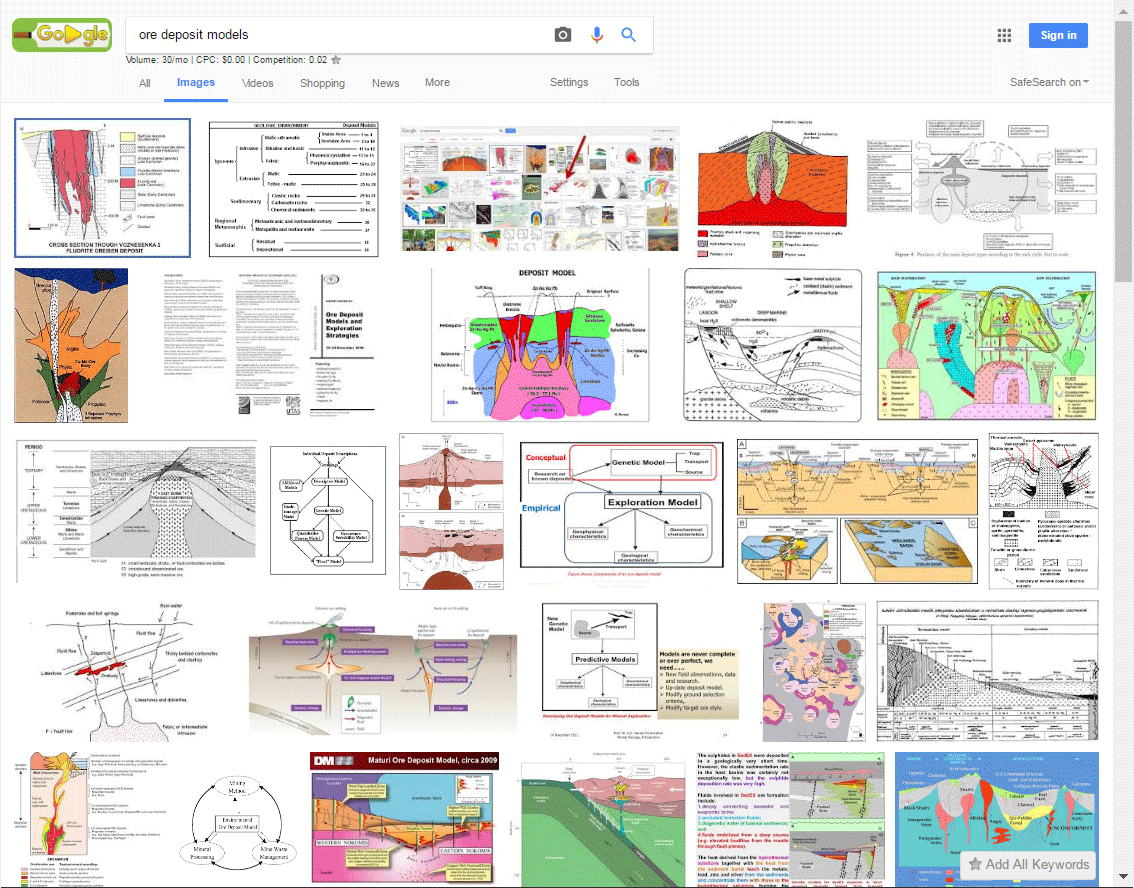

Modern ore deposit models formulated by academics largely ignore first-order mineralisation geometries—this can be simply demonstrated by searching for various ore deposit model types in Google Images (Cowan, 2012). Most published economic geology exploration concepts and ore body models are still based on 2D line drawings, a practice that has been going on since the 1970s (Figure 3). Cartoon-like ore deposit models continue to be used by mining companies as templates for regional exploration, despite them being poor predictors of mineralisation continuities (the formulation of these models lacks geometrical consideration). This is particularly true at the near-mine scale of analysis.

Figure 3. Search any ore deposit model types or geometries on Google Image Search and you will find the majority depicted are cartoon-like 2D line drawings or detailed tables. There are very few examples of actual 3D models of mineral deposits built from real drill hole data. Search phrases represented here from top to bottom are ‘ore deposit models’, ‘VMS deposit models’, ‘IOCG deposit geometry’ (search date 25 June, 2017).

Figure 3. Search any ore deposit model types or geometries on Google Image Search and you will find the majority depicted are cartoon-like 2D line drawings or detailed tables. There are very few examples of actual 3D models of mineral deposits built from real drill hole data. Search phrases represented here from top to bottom are ‘ore deposit models’, ‘VMS deposit models’, ‘IOCG deposit geometry’ (search date 25 June, 2017).

This ignorance may be a shocking fact to realise, especially for software makers who assume geologists are intimately aware of the 3D geometries of various mineral deposit types; therefore, these software makers boldly claim that their software ‘reduces geological risk’. To make such a claim, the software vendor totally depends on the assumption that geologists know how to model in 3D. The reality is that nearly all academics do not study, or have access to, multiple sets of drilling data from real deposits, so most are completely ignorant about the actual mineralisation geometries that exist in the real world that would benefit near-mine exploration or help generate accurate resource models (1). What these academics do is to refer to decades-old line drawings that are completely irrelevant for near-mine exploration or as templates for resource estimates, but this is what students of geology are taught as part of their education.

Poor structural geological education

Another major setback for the mining industry has been the degradation of structural geological education at the tertiary level over the last 50 years. Structural geological education, as well as field-based studies, has almost disappeared. Very few (possibly fewer than ten in the world) structural professors are seriously interested in applied economic structural geology; in the absence of applied structural geological education and research, there is a misconception that little or no relationship exists between mineralisation geometry and structural controls. This isn’t true, and it can be easily demonstrated (using 3D drilling data) that almost every mineral deposit is structurally controlled.

In the absence of structural geology knowledge being at the forefront of mineralisation geometry, geochemistry, which rarely references real 3D geometrical controls, has dominated the economic geological fraternity for the last 50 years, with two generations of geologists believing it to be THE most important topic to study. Academics are slow to realise that 3D geochemical alteration patterns are the product of structural architectural control, and without structural knowledge, geochemical patterns alone are ineffective for exploration. The so-called ‘vectoring’ that many geologists refer to is both a misleading statement and completely meaningless without first knowing the structural architecture and the state of strain of the host rocks. Without this crucial information, which the majority of academic researchers ignore, it is impossible to work out which way to ‘vector’, yet this term is routinely used in the mining industry.

Exacerbating this situation is the economic structural geology academics who have published theoretical structural concepts of mineralisation in the past, rather than actually examining 3D data sampled from drilling and understanding the real sampled drilling data. These conceptual structural models are ineffective at finding gold, as discussed by Vearncombe and Zelic (2015).

Poor structural education reflects on poor data collection

Almost all company procedures reflect this level of poor structural education. The level of good structural geological data collection from drill core from companies is extremely poor; possibly less than 10% of all operating exploration and mining projects collect the right information accurately (2). Even if the data is collected, it is unclear if anyone can use it effectively because they generally don’t know what to do with it and more commonly it sits in the corporate database and is never actually used. Again, software and service companies assume that geologists know what to do with collected structural data, but this assumption is incorrect.

Throwing the baby out with the bathwater

I conceived Leapfrog Mining software specifically from the perspective of acknowledging and realising that structural geology is the fundamental control—that mineralisation geometries are controlled by structural geological architecture. This is why the basic and fundamental tools that I asked to be programmed into Leapfrog Mining (which still survive into Leapfrog Geo) and the workflow (which did not get ported to Leapfrog Geo) were designed specifically for effective 3D structural analysis (Cowan et al. 2002, 2003). The fundamentals of this software were designed independently of the end user, as I knew the geological modelling being conducted in the industry at that time was completely inappropriate. The workflow of Leapfrog Geo is the reverse of Leapfrog Mining and uses logic that is similar to number of other modelling programs and is very stratigraphic in nature—it is a workflow that is completely irrelevant for the modelling of metamorphic rocks that have undergone several deformation episodes and that host most mineral deposits.

Innovation does not come out of general consensus

Innovations rarely come from public consensus and popular opinion, but from thinkers who don’t take for granted what is considered ‘common sense’ by the majority. This is not a new idea. Socrates knew this and ended up dying for his belief, some 2400 years ago.

Surprisingly, Leapfrog Geo was designed by public feedback and perceived customer needs; in the case of geological modelling, listening to feedback from customers who weren’t educated in the 3D structural controls of mineralisation. The only advice such users can give to the software maker is based on what they’ve always done—that is, workflows and processes they’ve learned from existing ineffective generalised mining products, or habits (e.g. modelling in sections), which have no relationship with effective analysis of mineral deposits.

Conclusion

The fundamental reason why many geological models could be completely wrong is because geologists are educated by academics who don’t know anything about 3D geometries of mineral deposits and are also taught to model deposits by software makers who are equally ignorant. Ironically, the software maker is under the illusion that the geologist and the academic actually knows a whole lot more than them, which is also isn’t true.

The claim of Leapfrog Geo software being able to ‘reduce geological risk’ hinges on the software makers’ assumption that the geologists (users) know, and can model, mineralisation patterns accurately to reflect what is really there. As discussed earlier I believe this is an incorrect assumption; therefore their claim that their software can reduce geological risk is nothing more than a fantasy, and I expect to see more failures of the magnitude of Phoenix mine to easily occur in the future.

What is happening in real life is a holy trinity of ignorance (Figure 1), where not one of the professionals who are interacting with each other appear to have a true intimate knowledge of the structural controls of 3D mineralisation patterns. Each party is under an illusion that others know more than them which isn’t the case. It should not be a surprise at all that major resource write-downs will continue to happen, even if the executives are true believers (Figure 2).

But users can avoid a costly mistake by studying structural geology and applying that knowledge to their interpretation of mineral deposits. This means analysing mineral deposits using the first-principles of structural geology—an issue that will be covered in future posts.

Footnote 1. At the recent Target 2017 conference in Perth, sixty-four papers and posters were presented by industry and academic exploration experts (Wyche and Witt 2017). The vast majority were conceptual and largely addressed regional greenfield targeting methodologies. Only one paper demonstrated a measurable economic benefit from applying a geophysical method to directly improve resource estimations at the grade control resolution (Wijns 2017), but apart from this no other paper demonstrated a direct benefit to exploration and resource estimation from the study of 3D mineralisation patterns analysed from densely sampled near-mine drilling (details of this discussion is found in Cowan, 2017).

Footnote 2. It is estimated from Orefind’s experience as consultants that perhaps 80% of companies orientate their drill core. Of this a majority either fail to check their orientation marks correctly and therefore their structural data are unreliable. The usable data is estimated to be <10% of all mines, and of these, very few actually measure useful structural data. Very few know how to use their data once collected and no company we have encountered has measured linear data, which is demonstrably the most important information for structural analysis of mineral deposits.

References

Cowan, E.J., Beatson, R.K., Fright, W.R., McLennan, T.J. and Mitchell, T.J. 2002.

Rapid Geological Modelling. In: S. Vearncombe, S. (ed.) Applied Structural Geology for Mineral Exploration and Mining International Symposium Abstract Volume. Australian Institute of Geoscientists Bulletin, 36, 39–41.

Cowan, E.J., Beatson, R.K., Ross, H.J., Fright, W.R., McLennan, T.J., Evans, T.R., Carr, J.C., Lane, R.G., Bright, D.V.,Gillman, A.J., Oshust, P.A. and Titley, M., 2003,

Practical Implicit Geological Modelling, Fifth International Mining Geology Conference Proceedings (Editor, S. Dominy). AusIMM Publication Series No 8/2003, p. 89–99. Reproduced with the permission of Australian Institute of Mining and Metallurgy.

Cowan, E.J., 2012,

The Deposit Model Paradox, Structural Geology and Resources 2012 - Extended Abstracts Volume (ed: J. Vearncombe), Australian Institute of Geoscientists Bulletin 56, p. 48-49.

Cowan, E.J., 2014,

‘X-ray Plunge Projection’— Understanding Structural Geology from Grade Data. AusIMM Monograph 30: Mineral Resource and Ore Reserve Estimation — The AusIMM Guide to Good Practice, second edition, p. 207-220.

Cowan, E.J. 2017.

Why can’t we interpret near-mine drilling data effectively? In: J. Vearncombe, J. (ed.) Mineral Exploration 2017 – Extended Abstracts Volume. Australian Institute of Geoscientists Bulletin. (Publication suspended as the originally planned symposium did not take place in August 2017. Will be published elsewhere).

Christensen, C.M. 1997. The innovator’s dilemma: when new technologies cause great firms to fail, Boston, Massachusetts, USA: Harvard Business School Press.

Financial Post, 2016. Rubicon Minerals Corp shares plunge as miner slashes its gold resources by 88%. (http://business.financialpost.com/news/mining/rubicon-minerals-corp-shares-plunge-as-miner-slashes-its-gold-resources-by-88) [accessed 16 June, 2017]

Vearncombe, J. and Zelic, M. 2015. Structural paradigms for gold: do they help us find and mine? Applied Earth Science (Trans. Inst. Min. Metall. B) 124, 2–19.

Wijns, C. 2017. Geophysics at the small end of the scale: understanding the resource. In: Wyche, S. and Witt, W.K. (eds.) TARGET 2017, Perth, Australia: abstracts: Geological Survey of Western Australia, Record 2017/6, 163–165.

Wyche, S. and Witt, W.K. (eds.) 2017. TARGET 2017, Perth, Australia: abstracts: Geological Survey of Western Australia, Record 2017/6, 166p.