1965 Nobel Prize ceremony - Richard Feynman and the Princess of Sweden (http://www.richard-feynman.net/index.htm)

"It doesn't matter how beautiful your theory is, it doesn't matter how smart you are. If it doesn't agree with experiment, it's wrong."

- Richard P. Feynman (theoretical physicist)

He was a dapper, confident, ladies’ man. A New Yorker with a devil-may-care attitude, but also had a softer side. He shunned pomp and ceremony and hesitated bowing down to the King of Sweden to accept his Nobel Prize. He was Richard Feynman (1918–1988)—a highly celebrated physicist who contributed greatly to the field of quantum physics.

But why am I discussing a physicist in a post mostly read by geologists?

Well, that’s because Richard Feynman had an interesting life-long habit—an insistence—of using ‘first principles’ in trying to solve any problems he worked on. Feynman used the first-principles approach to solving problems other than science, including how to pick locks, how to sketch portraits, and even deconstructing the most effective ways of picking up women in bars. He believed that any seemingly complex skill can be learned by breaking down the process into fundamental principles.

I believe we geologists don’t go back to first principles enough in mining and exploration. Instead we recycle, regurgitate, and almost entirely depend on rules and ore deposit models (formulated by academics and established since about the 1970s) to solve our exploration and mining problems. Typically, we don’t question these ore deposit models, which are often very vague and so flexible that they are rendered meaningless as an exploration tool. Geologists almost always assume ore deposit models are correct without conducting any rigorous independent tests. This is exemplified by geologists’ habit of categorising exploration projects almost immediately after discovery by calling them VMS, SEDEX, Shear Zone Hosted, Igneous Hosted deposit, and so on. Instead of rigorously interpreting our data and coming up with a hypothesis that can be tested, we tell over-complicated stories to force-fit our data into one of the academic ore deposit models.

As a community, we no longer see the value of completely independent analysis, and thus rarely look closely at data collected by mining companies to determine what these data actually mean. What we now do is not science, but pseudoscience by rote learning, and in my mind this default mode of interpreting deposits has seriously stymied the advancement of applied geological science.

Feynman always worked from first principles, despising rote learning and arm-waving ideas that could not be practically tested. No matter how complicated the problem, he insisted his students understand the basic principles and deconstruct the problem into simple, easily explained components. If he couldn’t explain the problem to a freshman physics student, it meant that he (as the teacher) didn’t understand the problem. Because of his steadfastness to this simple approach, I believe he contributed greatly to the field of physics.

Geologists can learn from Richard Feynman’s approach, which is why I want to tell you about first principles. I will then leave you with two geological examples applying the first-principles approach from my own consulting work and outline the value of this methodology.

The scientific method—it was no joking matter for Feynman

Richard Phillips Feynman was a remarkable 20th century physicist. His best-selling autobiography Surely You’re Joking, Mr. Feynman!: Adventures of a Curious Character (Feynman, 1985) is a witty account of his life told in series of short, interesting, and funny experiences. He doesn’t detail the various physics problems he worked on—instead, he outlines his beliefs and what amused him. You could say the book is an outline of his philosophy of life, although I shouldn’t use the word ‘philosophy’ because he didn’t like philosophers—to him, they came up with multitudes of untestable theories, an approach he found unsatisfactory.

Feynman had a somewhat eccentric habit—he would ask colleagues what problem they were working on. They would tell him the problem, then proceed to outline their approach to solving the problem, but Feynman would cut them off mid-sentence, and would rush off. He never wanted to know their approach to a solution because that didn’t interest him. Instead he would work on their problem on his own using his first-principles approach and would later tell his colleagues how he solved the problem (Gleick, 1992). Sometimes he would come up with a novel and elegant solution that the colleagues had not considered, much to their astonishment. This process was a game to him, and he revelled in the completely independent process of solving problems. He wasn’t interested in being influenced by others, but only wanted to work things out for himself from first principles, simply because that gave him joy.

Perhaps the most famous example of his independent approach was his contribution to quantum electrodynamics, for which he, Shinichiro Tomonaga, and Julian Schwinger were jointly awarded the Nobel Prize in Physics in 1965. Julian Schwinger approached quantum electrodynamics from a more traditional mathematically rigorous approach, which was accepted almost immediately by the scientific community. In contrast, Feynman’s description of quantum electrodynamics was not appreciated for many years, because it was based on a novel approach and was unfamiliar to the physics community. However, once his methods gained acceptance, they became very influential. Feynman invented strange diagrams to represent various interactions between different subatomic particles—now referred to as Feynman diagrams—that condensed complicated probabilistic mathematics into simple illustrations. This was a revolutionary idea and a new approach—an idea borne out of working from first principles. A somewhat analogous approach used in geology is the simple Mohr’s Circle diagram, which represents complex mathematical algebraic equations, used in stress analysis.

In the physics community, Richard Feynman’s insistence on working out problems independently was not normal behaviour. Most physicists relied on ‘common knowledge’ based on previous work; however, the downside is that ‘accepted, established fact’ can sometimes be incorrect. Often errors were later found to be introduced because the researchers were influenced by, and reliant on, previous work.

Instead, Feynman was always curious about solving problems from first principles, thus avoiding this trap and often approached old problems from a completely new angle. It was a habit he established in childhood when he set up a lab in his bedroom. This early discovery process, resulting from childhood curiosity and working out solutions himself relying only on basic principles, made him a very successful scientist later in life. All Richard Feynman did was to apply his basic scientific method to all the problems he worked on.

Feynman’s 3-step scientific method

There are many ways to explain the scientific method (e.g. Vann and Stewart, 2011), but as Feynman explains in the first minute of this 1964 lecture at Cornell University, it boils down to just three steps:

Step 1: Guess

Step 2: Compute the consequences of the guess

Step 3: Compare directly to nature/experiment/experience/observation.

He points out that if the predicted consequences (Step 2) made as a result of the initial theoretical construct/guess (Step 1) do not agree with what is observed in nature (Step 3), then the guess is wrong. In the video he gesticulates this message with his expressive body language, while the students in the audience respond with laughter.

"If it disagrees with experiment, it’s wrong. In that simple statement is the key to science. It doesn’t make a difference how beautiful your guess is, it doesn’t make a difference how smart you are, who made the guess, or what his name is. If it disagrees with experiment, it’s wrong. That’s all there is to it."

- Richard P. Feynman

I’ll apply this 3-step process to the interpretation of two deposits (below), but before I do, the fundamental principle I rely on when interpreting mineral deposits for making my initial guess (Step 1) is:

Mineral deposits are always controlled by structural architecture.

(The exception is placer deposits, which are controlled by depositional architecture.)

This principle has been reinforced and validated time and again from viewing about 700 sets of drillhole data over my career, and is a prerequisite to my approach (Cowan, 2014). Consequently, I’ve concluded that knowledge of structural geological theory is the most important prerequisite for the interpretation of mineral deposits, and I believe it is more important than any other geological skill. Without the ability to understand and interpret strain patterns, geologists are completely disadvantaged. I know that many geologists (and academics) will disagree with my view because structural architecture and 3D geometry doesn’t play a part in formulating almost all published ore deposit models (Cowan, 2012).

The reason I know structural architecture is essential in mineral exploration is that I can make accurate predictions using Feynman’s 3-step process that are impossible to make from just applying published ore deposit models to exploration.

If structural geology is not important, then my predictions based on structure will fail at Step 3 of Feynman’s approach. That is how the scientific process is supposed to work, so I’m comfortable with that.

First, I’ll discuss a case study where the 3-step process works perfectly, then another where the 3-step process fails, but I’ll also explain the failure.

Geological Case Study 1

At this gold deposit, the control of the mineralisation was previously described by a well-known academic consultant. The consultant explained the mineralisation in terms of a VMS ore deposit model and did not document structural architecture, despite acknowledging there are at least two phases of folding. The consultant made no recommendations as to the specific control of the mineralisation, other than refer to idealised pre-deformational VMS models that couldn’t be tested.

My visual assessment of the assay data predicted that gold is likely to be distributed along S1 foliation surfaces. My Step 1 guess is that there is structural control. Step 2 is then to create specific patterns that I expect in such a scenario.

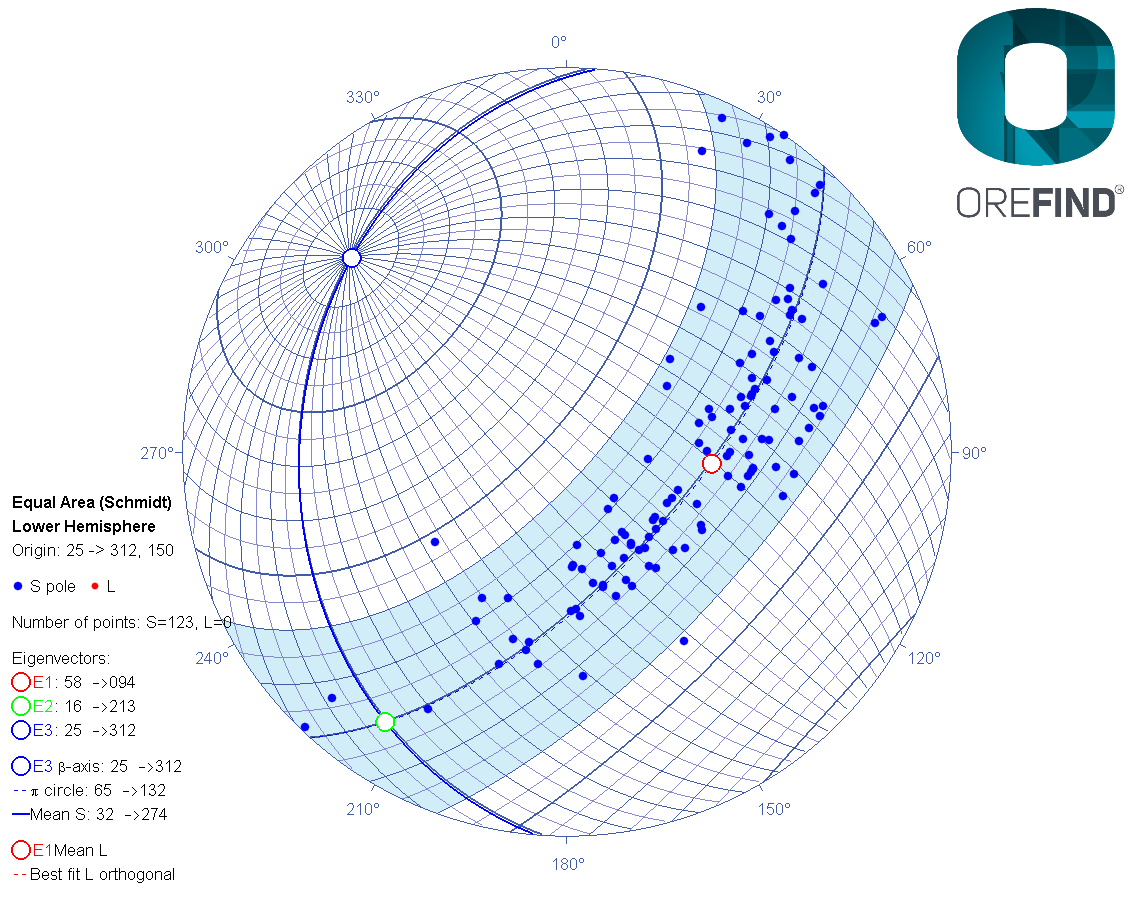

The stereonet in Figure 1 shows a set of S1 foliation poles. Other than the rotated grid and shading, which allows me to analyse structural symmetry, I’m sure these plots are familiar to most geologists.

Figure 1. S1 foliation data

If you look closely, there’s something unusual about this plot. You’ll notice that the poles are almost perfectly clustered along the best-fit great circle—this clue gives it away that this is actually a synthetic dataset. This is my informed guess of the approximate distribution of foliation readings I expect to find at a site of a deposit. That is, it’s an a priori deduction—

my Step 2 prediction, which is made before someone else actually obtains some foliation readings. (Note that I estimate these foliations in true geographic space, but for the sake of anonymity only a stereonet summary is presented here.)

As an aside, when I refer to ‘someone else’ to do the field work, I mean anyone other than me. Yes, I could do the field work, but that wouldn’t make it an independent experimental process, so I prefer to have my business partner (Brett Davis) fly to site and conduct the field work independently from my own guesses. This ensures that Step 3 is based on an independent experiment.

For this deposit, I asked the client to not send me any existing structural data, which meant that I could only formulate my guess from the assay and lithological data from drilling. I had to work out the structural controls just using grade distribution. Once I made the guess and sent it to the client (Figure 1), I asked the client to send me their actual measured foliation data, which is shown beside my guess in Figure 2.

Figure 2. Guessed (right) and actually measured (left) foliation poles.

The F2 fold axis plunges to the NE at very similar orientations for both plots (Figure 2), and the north-dipping bias of the foliation is similar (

Step 3—field testing the prediction). Although F2, in reality, is much more non-cylindrical, the plunge is very close to my guess, and not a bad one for a structural interpretation obtained from just grade data. This result is very specific and much more informative than that provided by the academic consultant who applied the VMS model but couldn’t provide anything specific. This experiment was a success, and my ‘guess’ was accurate. Now that it has been ground-checked, my prediction can be relied on. Passing Step 3 is my proof that I don’t always need traditional structural data to interpret the structural controls of mineral deposits.

Geological Case Study 2

In this next example of the 3-step scientific process applied to mineral exploration, the test fails. I made the guess from a mining property, and then predicted patterns in an adjacent exploration area 2.5 km away.

In this deposit I interpreted that the mineralisation was largely controlled by bedding (Step 1—my initial guess). Figure 3 is a stereonet of my expected bedding orientations from the base-metal deposit being mined; however, bedding readings were never measured at this mine because the drill cores were never orientated and structural mapping was not conducted. Similar to the first example, I used grade distribution and ore wireframes created independently by the mine geologists to establish my expectations of the bedding orientations (Step 2—expected patterns) (Figure 3).

Figure 3: Guessed bedding poles from the main deposit.

Figure 3: Guessed bedding poles from the main deposit.

This guessed bedding distribution (Figure 3) was made to predict the expected bedding orientation at a nearby exploration site, which was being drilled. This time, the drill cores were orientated and the bedding readings were measured by the exploration geologists using the alpha-beta method (Blenkinsop et al., 2015). As with Case Study 1, I was not involved in the data measuring process.

Figure 4 shows the bedding patterns from the exploration drill holes (Step 3—comparison with nature). The bedding poles in Figures 3 and 4 are completely different, with the folds plunging in opposing quadrants.

Figure 4. Measured bedding from the orientated drill core from the adjacent exploration site.

Using Feynman’s 3-step process, I had to conclude that my guess of the bedding control was incorrect to begin with, or my predicted pattern was incorrect. But was this truly the reason? I didn’t think so. I was very confident of the guessed bedding orientations, so I investigated possible errors in how the bedding data was measured from the orientated core.

Those who have read Brett Davis’ blog posts on analytical errors produced from orientated core structural measurements (summarised in Davis, 2014) will understand that many things can go wrong. My immediate reaction was that the data was correctly measured relative to the core, because the poles were not distributed haphazardly or in small circle distributions about the drillhole plunge, which would suggest core spin. However, a very real possibility was that the beta angle was measured incorrectly by marking the core in an unexpected way, possibly from the top of the core.

The company confirmed my suspicions, telling me that the core orientation line was marked on the top of the core (because of the electronic core orientating device they used), rather than the traditional convention of marking the bottom of core. But their beta measurements were recorded as if the orientation line was on the bottom of core. There was no indication in the structural table that the beta measurements were not relative to the bottom of core, so I had applied the default method for alpha-beta conversion to dip/dip-azimuth readings. Once this error was realised, the beta angles were changed by 180° and the bedding readings were orientated to their expected orientations. The comparison between predicted bedding and the corrected version of the measured bedding from the exploration site is shown in Figure 5.

Figure 5. Guessed (right) and measured (left) bedding poles after beta values were corrected.

Again, the result of this comparison confirmed my guess to be accurate, although it appears that the fold plunge in the exploration area is at a lower angle to the NW. It is worth noting that the correction to the beta angles could only be done because I followed the 3-step scientific process outlined by Feynman. If I had not predicted what bedding orientations to expect and just blindly collected data, I may not have picked up the error in the beta measurements until much later—or at all.

Implications of the case studies

These two case studies demonstrate that the structural control of mineral deposits can be estimated accurately without collecting any structural measurements, and can then be independently verified with structural field work using Feynman’s 3-step scientific method.

Many company geologists completely ignore this useful approach.

Companies often bring me in to look their data. They might have abundant multi-elemental data and a complete lithology table, yet they lament that they don’t have any knowledge about the structural control of their mineral deposit because they haven’t sent a structural geologist to site.

Let’s just stop and think about what they are saying here, because this logic makes no sense to me...

If a mineral deposit is structurally controlled (and I would argue virtually all mineral deposits are), then the structures should be visible in grade and alteration distributions. This makes perfect sense to me (Cowan, 2014), yet most geologists do not view the assay data as a suitable dataset from which structural controls can be directly interpreted.

It’s as if geologists have been put under a mysterious spell to stop thinking, and they’ve forgotten why they want to collect structural data in the first place! The why is to know the structural control of their deposit, so they can predict the positions of mineralised extensions.

Collecting structural data, such as shear, vein, bedding, and cleavage orientations from a mineral deposit, only provides an indirect insight into the structural controls of mineralisation—structural geologists still have to infer the larger-scale mineralisation patterns from the structures identified in the field.

I would argue that a quicker and more direct method is to simply examine the grade distributions.

If mineralisation is controlled by structural geology, then the evidence of structural control (in the form of preferred grade distribution) should be evident if you have enough assay data from drilling to look at. Even if you have very little drilling data, you can still make some reasonable assumptions that can be tested using Feynman’s 3-step process.

Conclusions

“What I cannot create, I do not understand”

- Richard P. Feynman.

In other words, if we can’t guess what the exploration data means geologically, then we don’t understand it. Period.

Making a guess from the observed primary data is the crucial first step in scientific deduction and analysis. We can then test our guess.

In the two geological examples discussed above, I showed that I correctly understood the structural controls of the mineralisation and then made a testable prediction that could be independently verified from field measurements collected by a third party. This is not a conveniently vague, fluffy, self-fulfilling prophecy that I can fudge by circular reasoning, but follows an independent scientific experimental procedure. I didn’t need an ore deposit model to anchor my interpretation. I don’t see the relevance or the need for such a model because I can make accurate and verifiable predictions that I need for exploration from analysing primary data using ‘first principles’ of structural geology.

However, this approach is not an everyday occurrence in the mining industry.

Often exploration data is interpreted in the framework of an established theoretical model, which can’t be practically tested or proven in a simple, understandable way. Ore deposit models are often vague, nebulous and characterised by many permutations, which allows them to be applied to almost any geological scenario, whether the model is suitable or not. Critically, there is no structural or geometric framework for almost all published ore deposit models (Cowan, 2012), so specific structural predictions can’t be made. This is a real problem, considering most deposits are structurally controlled.

As demonstrated by the academic consultant who worked on the deposit in Case Study 1, ore deposit models often fail at Step 2, where a specific prediction should be formulated for testing. However, specific predictions with the level of precision demonstrated in the case studies in this post using first principles of structural geological cannot be made with most ore deposit models because models are too vague and not predictive enough.

Feynman pointed out in his Cornell University lecture that one cannot prove a vague theory wrong. This is because vague theories lead to vague or indefinite consequences. Feynman said of testing vague outcomes: ‘with a little skill any experimental result can be made to look like an expected consequence’. He argued if you cannot make precise predictions from your guess, then you cannot claim to know anything about it.

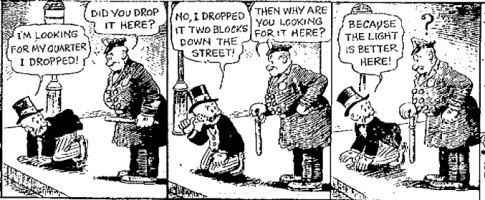

Geologists who use ore deposit models, which might be relevant at the regional scale but can’t identify specific drilling targets at the deposit scale, often resort to seemingly technical statements such as being able to ‘vector into mineralisation’, without making a useful specific prediction that can be practically tested with drilling. Proponents of ore deposit models often focus on completely irrelevant details that don’t directly help identify areas to drill. This is the embodiment of ‘the street light effect’ (Figure 6), where explanation focuses on issues that are irrelevant or only marginally relevant to addressing real exploration problems.

Figure 6. The streetlight effect is a type of observational bias where people only look for whatever they are searching by looking where it is easiest.

Figure 6. The streetlight effect is a type of observational bias where people only look for whatever they are searching by looking where it is easiest.

Many ore deposit academics have ignored structural control of mineral deposits for many decades. This is largely because the majority of these academics—who formulated many of the ore deposit models—didn’t consider structural geology to be of any importance when they formulated their models.

Yet structural geology is an essential skill in mineral exploration and mining because it can lead to predictable exploration targets. The critical importance of structural knowledge for the mining industry can be practically demonstrated. It is time for the mining industry to embrace structural geology as a fundamental core skill required in exploration and mining, and start applying Feynman’s 3-step scientific method to advance our science to the next level.

I believe this is exactly what Richard Feynman would have done, had he been a geologist.

---

Jun Cowan, PhD, is a director and principal structural geologist of consulting firm Orefind, and the conceptual founder of Leapfrog geological modelling software. He holds an Adjunct Senior Research Fellow position at the School of Geosciences, Monash University.

Based in Fremantle, Western Australia, Orefind is a geological consulting company founded by structural geologists Brett Davis and Jun Cowan. Visit www.orefind.com for more information. This post, and many more like this, can be found on the Orefind website. Constructive feedback is always gladly appreciated.

References

Blenkinsop, T., Doyle, M. and Nugus, M., 2015, Unified approach to measuring structures in orientated drill core. In Richards, F.L., Richardson, N.J., Rippington, S.J., Wilson, R.W. and Bond, C.E. (eds). Industrial Structural Geology: Principles, Techniques and Integration. Geological Society, London, Special Publications, 421, 99–108.

Cowan, E.J., 2012, The Deposit Model Paradox, Structural Geology and Resources 2012 – Extended Abstracts Volume (ed: J. Vearncombe), Australian Institute of Geoscientists Bulletin 56, p. 48–49.

Cowan, E.J., 2014, X-ray Plunge Projection— Understanding Structural Geology from Grade Data. AusIMM Monograph 30: Mineral Resource and Ore Reserve Estimation — The AusIMM Guide to Good Practice, second edition, p. 207–220.

Davis, B.K., 2014, Use and Abuse of Oriented Drill Core. AusIMM Monograph 30: Mineral Resource and Ore Reserve Estimation — The AusIMM Guide to Good Practice, second edition, p. 121–134.

Feynman, R.P., 1985, Surely You're Joking, Mr. Feynman!: Adventures of a Curious Character. W W Norton.

Gleick, J., 1992, Genius: The Life and Science of Richard Feynman. Vintage Books.

Vann, J. and Stewart, M., 2011, Philosophy of science: a practical tool for applied geologists in the minerals industry. Applied Earth Science (Trans. Inst. Min. Metall. B), 120, 21–30.