In a previous blog I lamented the oft-encountered situation of geologists lacking basic structural geological skills. In this contribution, I will focus on a skill that is rarely used but that can be extremely powerful in terms of the information it can provide. I am referring to the use of oriented samples. Oriented samples are essentially portable outcrops that allow structural measurements to be taken in the coreshed/office etc. Ease of examination is enhanced by being able to cut the samples in any orientation desired, thus allowing a view of structural relationships on fresh faces.

Oriented samples are portable outcrops

Historically, the mining industry has interpreted geological and resource models based on sections parallel to drill fences, and on plans at various RL’s. Unfortunately, the sectional orientations are commonly not ideal for viewing geological relationships crucial to understanding the geological architecture and geometry of mineralisation.

Mine and exploration grids are typically established such that they have orthogonal relationships with the trend of mineralisation. However, the controlling structures, ore shoots, subsequent structures that cause modification, various vein sets etc will invariably lie at variable angles to the established grid. Consequently, the best understanding of a deposit is a product of viewing the grade and geological relationships from various orientations. Essentially, traditional sectional interpretation is a flawed method for modelling geology. Jun will elaborate on this in future blogs.

One of the most powerful things about oriented samples is that they can be cut parallel to drill section orientations, and/or parallel to section orientations that give the best view of geological relationships in 3D models. Apparent dips and kinematic relationships can be transferred directly to the sections. Furthermore, horizontal slices can be made that allow strike information and kinematic relationships to be transferred directly to plans. By establishing the best viewing orientation to examine structural relationships, the oriented samples can be cut normal to this.

Unfortunately, Orefind has found it that geologists in industry rarely know how to take an oriented sample. All it takes is the ability to measure a dip and dip direction. Sadly, some people don’t even know how to do this. For these reasons, this blog concentrates on the process of taking an oriented sample.

Procedure for taking an oriented sample

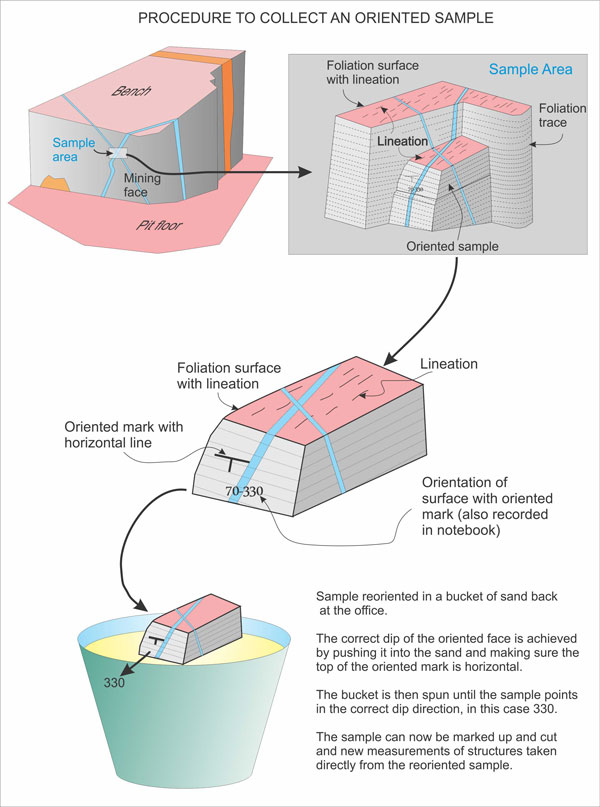

Figure 1 shows the procedure for taking an oriented sample. The rock with structures to be examined is selected and a dip and strike symbol is placed on a flat surface. The top of the dip and strike symbol needs to be horizontal and the edge of a compass with a leveling bubble can be used to determine this. Note that the surface just has to be flat – it does not have to correspond to bedding or a cleavage. The orientation of the surface is recorded – in this case it dips at 70° toward 300° (dip and dip direction).

Figure 1

Figure 1

Method for taking an oriented sample.

Sometimes the surface on which the mark is placed will be overturned. Make sure that a note is made of this and the appropriate symbol placed on the overturned surface. The reason for this is as follows: Take the sample in Figure 1. It could have a parallel face dipping at 70° toward 300° (dip and dip direction) at the back of the sample (Figure 2). However, this parallel face would need to be overturned and needs to be indicated as such so that the sample can be correctly reoriented (Figure 2).

Figure 2

Figure 2

Cartoon showing how the relationship between faces that are overturned and right side up.

The sample is removed making sure that the orientation mark is retained and taken back to the coreyard/laboratory and reoriented. The best way to do this is to place the sample in a bucket of non-magnetic sand. Make sure the dip symbol is horizontal and then rotate the sample forward or backwards to duplicate the dip measured in the field. Then rotate the whole bucket until the correct dip direction is achieved.

The sample is now oriented. It is a simple matter to use a compass to mark the desired orientations to cut the sample. Figure 3 shows two planes that have been marked. In this case a N-S vertical section (blue) has been marked and this could be parallel to a drillhole fence. The other section marked is a horizontal plane (red). The right hand figure shows the sample that has now been cut parallel to the N-S plane. A vein and a cleavage can be seen on the cut section. The apparent dips of these structures can be transferred directly to the N-S drill section (bottom of Figure 3).

Figure 3

Figure 3

Cartoon showing how the apparent dip orientation relationships of structures exposed in a cut oriented sample can be transferred directly to a cross section.

As noted above, the best direction to view structural relationships may not be orthogonal to surveyed mine and/or exploration grids. Typically, an orientation oblique to the surveyed grid is determined as best for viewing geological relationships. Software such as Leapfrog plays a critical role in determining the best direction of viewing. It is a simple matter to mark out an oblique plane on the oriented sample that is orthogonal to the oblique viewing direction. This is then cut and orientations measured in the same way as for the vertical plane

Oriented samples are a permanent record of structural relationships

As an example of the use of oriented samples, I undertook a seven month study of the structural controls on gold at the Kanowna Belle Gold Mine in the Eastern Goldfields of Western Australia. I collected over 300 oriented samples during the study and these were ultimately the only record of the structural relationships in many parts of the mine. Many of the original sample sites were from planned stope development and were subsequently destroyed. The only way structural relationships in the mineralised portions of much of the mine can be revisited is if the oriented samples are used.

As a final note, I would say that it is always better to collect a sample and not need it as opposed to not having a sample at all. In addition, if a sample is collected it should be oriented. It is the same argument as for diamond drilling. If a hole is drilled then it should be angled and there needs to be a good reason for why it is not oriented. Geology is a fickle beast and we need to collect all the information we can.