When Leapfrog Geo v.1.2 was

released on 25 February 2013, it was promoted as a replacement for Leapfrog Mining (originally called ‘Leapfrog’). However, I could only shake my head in disbelief when I discovered that Leapfrog Mining’s elegant drawing tool was not available in Leapfrog Geo. This drawing tool was invaluable if you knew how to use it correctly.

Leapfrog drawing tool downgraded for Leapfrog Geo

Around 2007, I was told by a senior R&D staff member from ARANZ* that the next major release of Leapfrog wasn’t going to include Leapfrog Mining’s drawing tool. The reasons given included ‘most users found it extremely difficult to use’, and ‘Jun, you use Leapfrog completely differently from other people, and your way is not necessarily the only way or the right way’.

Interesting comments, given that I had come up with the Leapfrog concept. In April 2001 I contacted ARANZ, a small tech company in Christchurch that had no experience in mining or geology and was dependent on NZ government research grants. At the time, ARANZ developed and owned

FastRBF, a radial basis function (RBF) interpolation code that was used in

modelling laser scan and other scattered point data. When I found FastRBF via a Google search, it was a Eureka moment that only happens once in a lifetime—I knew that rapid 3D interpolation would completely change the way we viewed and understood geological data gathered from drill holes.

The

Leapfrog website doesn’t describe how ARANZ moved into the field of modelling geology. That’s likely because they didn’t come up with the idea—I did, but that’s another story for another post. Nor did they come up with the specification for the drawing tool that was developed for Leapfrog Mining. Again, some very specific features included in that drawing tool came from me based on careful thought and with clear vision borne from my structural geological experience; the coding, execution and finesse was by some very talented people at ARANZ.

Dr Hughan Ross was invaluable as the Chief Architect of the software. However, one of the most significant contributions to the Leapfrog tools came from Dr Richard Lane, an electrical engineer who had worked as a lecturer and researcher at Canterbury University and who joined ARANZ in 2003. Richard took on the role of coding Leapfrog Mining’s drawing tool—his coding was brilliant and greatly enhanced the capability of the software. Richard came up with several very innovative tools within Leapfrog Mining, but the overall design of how these tools interacted came from my conceptual input and long discussions with Hughan followed by Hughan’s well thought-out translation from my vision to code. This perfect blend of three equal inputs into the development of Leapfrog Mining is summarised as a ternary diagram, below (Fig 1).

Figure 1. Building of the original Leapfrog Mining came from three equally important inputs. From ARANZ, Dr Hughan Ross was responsible for the graphical user interface (GUI) and Dr Richard Lane was responsible for the R&D and generation of specific tools, such as the drawing tool. From SRK Consulting in Perth, I was responsible for the geological vision. My input often ignored what was developed in conventional mining software because we were dealing with a disruptive technology.

Figure 1. Building of the original Leapfrog Mining came from three equally important inputs. From ARANZ, Dr Hughan Ross was responsible for the graphical user interface (GUI) and Dr Richard Lane was responsible for the R&D and generation of specific tools, such as the drawing tool. From SRK Consulting in Perth, I was responsible for the geological vision. My input often ignored what was developed in conventional mining software because we were dealing with a disruptive technology.

After working very hard on this product for many years (2001-2007), it was disheartening for me to hear that the drawing tool that was designed out of great collaboration was not to be included in the supposedly ‘vastly improved’ next generation of Leapfrog (later named Leapfrog Geo).

As the Leapfrog Mining software sales took off, slowly but surely, the relationship shown in Figure 1 changed. Eventually the developers dropped the drawing tool from Leapfrog Geo, and now most ARANZ Geo* staff have no idea of the origins of Leapfrog Mining (probably other than the fact that it is ‘old school’ and should be forgotten!).

Disruptive innovation

This post is not just about one tool. However, I’m using the drawing tool as a way to explain the strategy of building disruptive software, because it offers a lesson to individuals and companies that develop disruptive technologies within established markets. A

disruptive innovation is an innovation that helps create a new market, and eventually disrupts an existing market displacing an earlier 'sustaining' technology (

Christensen 1997). The invention of the car effectively displaced the horse and cart. Digital camera displaced the chemical film. Similarly implicit geological modelling

has the potential to displace the wireframe-based GMP software products in the mining industry.

If executed correctly, disruptive technologies can completely change and lead an entire industry (e.g. iPhone/Android); conversely, if not executed correctly, they can be relegated to the dustbin filled with other past technologies (e.g. Blackberry). Note that in the case of the Blackberry devices, these were at one stage disruptive to older technologies such as Nokia/Ericsson phones, but the tide can quickly turn and the disruptors can become a victim of new disruptions themselves. This post is about this cyclical disruption process and my personal views on product design of disruptive technologies using Leapfrog's drawing tool as an example.

But first I need to explain how the drawing tool came about, the reasons for how it was designed, and the justifications for the design. If you’re just interested in learning the lesson, then assume that the tool as it was designed is fully justifiable and skip to

Part 2 of this post, which discusses how the relationship shown in Figure 1 changed and the reason the original drawing tool was discarded in Leapfrog Geo.

Leapfrog drawing tool – the paradigm shift occurred ten years ago

In 2004

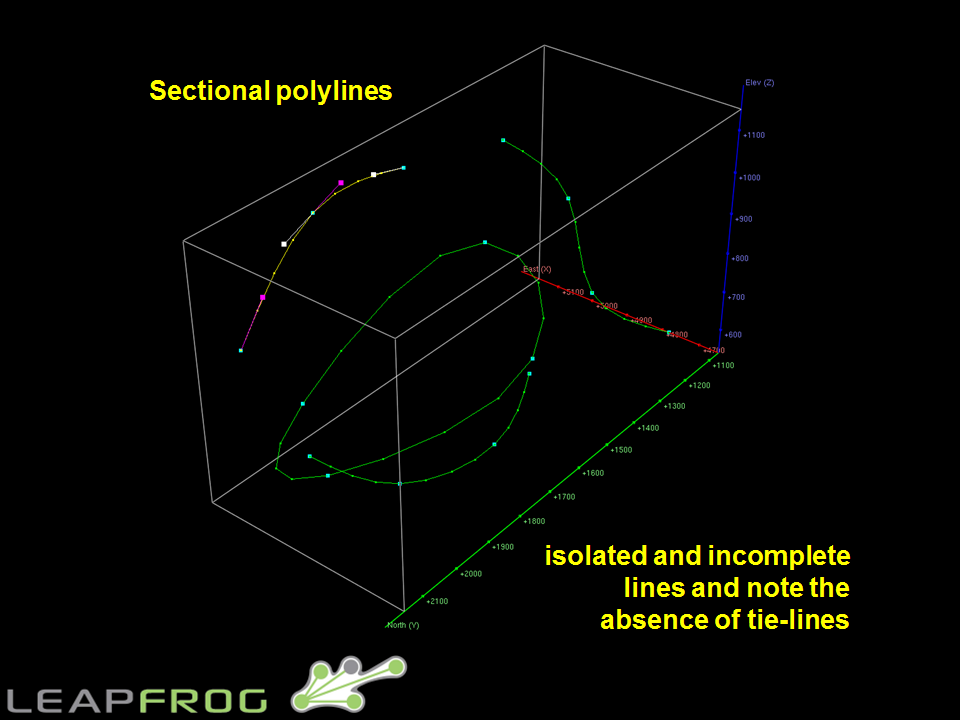

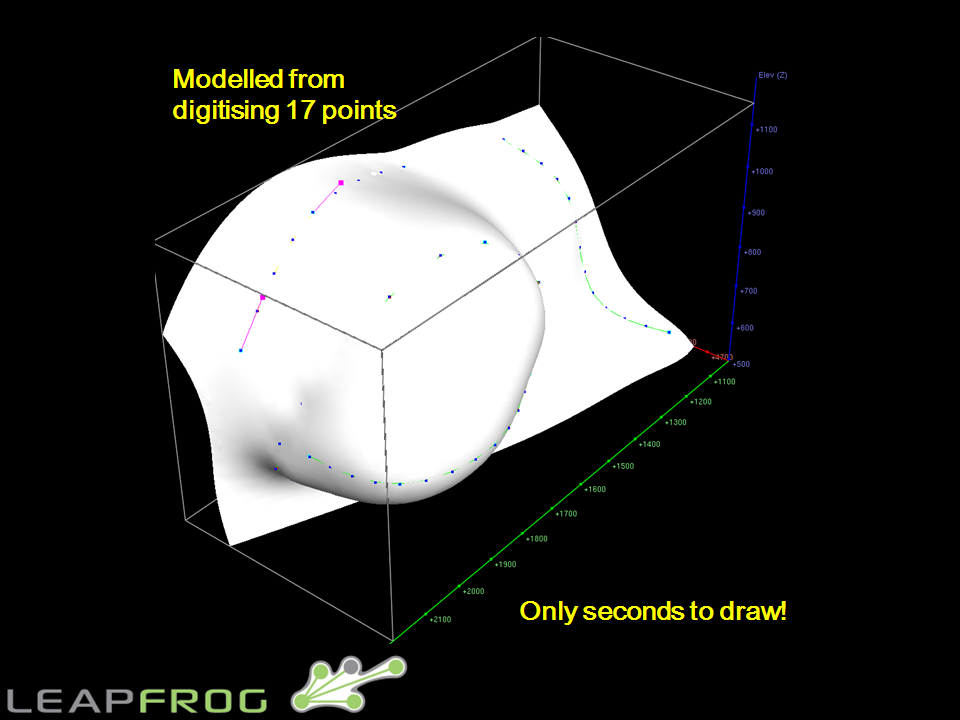

Zaparo Ltd** developed a free-form drawing tool that was to be included in version 1.5 of Leapfrog (later called Leapfrog Mining). Potentially, this was a revolutionary tool that allowed geologists to easily draw 3D objects of any shape with polylines; however, the polylines didn’t have to be connected to each other with tie lines as is required in all CAD-based generalised mining products (GMPs). This drawing tool was one of the highlights of my time working for the Leapfrog development project (2001–2007) (I was the General Manager of Zaparo at the time). In 2001, this rapid drawing concept was just an idea and to see it actually come alive on screen the way I envisaged it was an amazing experience.

Leapfrog’s original polyline drawing tool was designed and coded by Dr Richard Lane after I asked him specifically to build a Bézier curve drawing tool for Leapfrog. This was successfully implemented in only a couple of weeks by Richard, who is brilliant at solving well-specified problems. This drawing tool, which has changed little from its original form and is still available in the current version of Leapfrog Mining, was elegant because it was simple yet very powerful.

There were no other drawing tools like it on the market at the time in 2004 (nor in 2015), even outside the mining market—the Leapfrog drawing tool was a paradigm shift in 3D drawing.

Most people didn’t understand the significance of this drawing tool when I gave a talk about it at an Australian Institute of Geoscientists (AIG) meeting in Brisbane (

Cowan, Lane and Ross, 2004). At the time, we hadn’t developed a prototype so I demonstrated it using PowerPoint slides (some of these images are included below). I think most of the audience couldn’t believe this drawing tool would make a difference in the mining industry because the existing implementation and use was nothing like their traditional drawing tools (was it too good?). Moreover, it was not developed as part of a GMP (such as Vulcan, Surpac etc.), and thus lacked credibility within the industry.

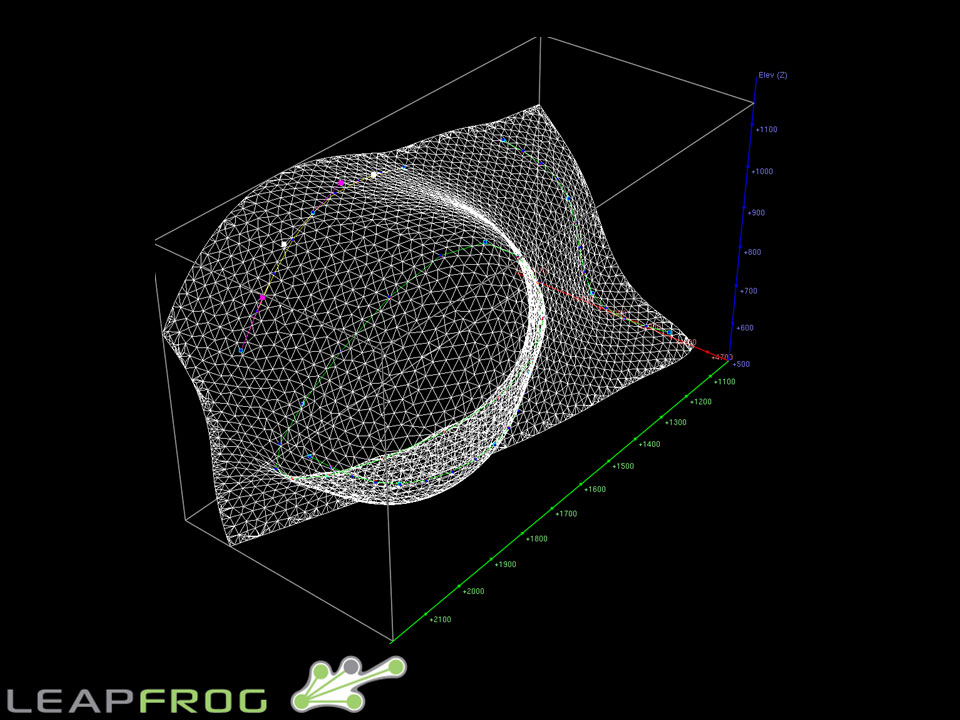

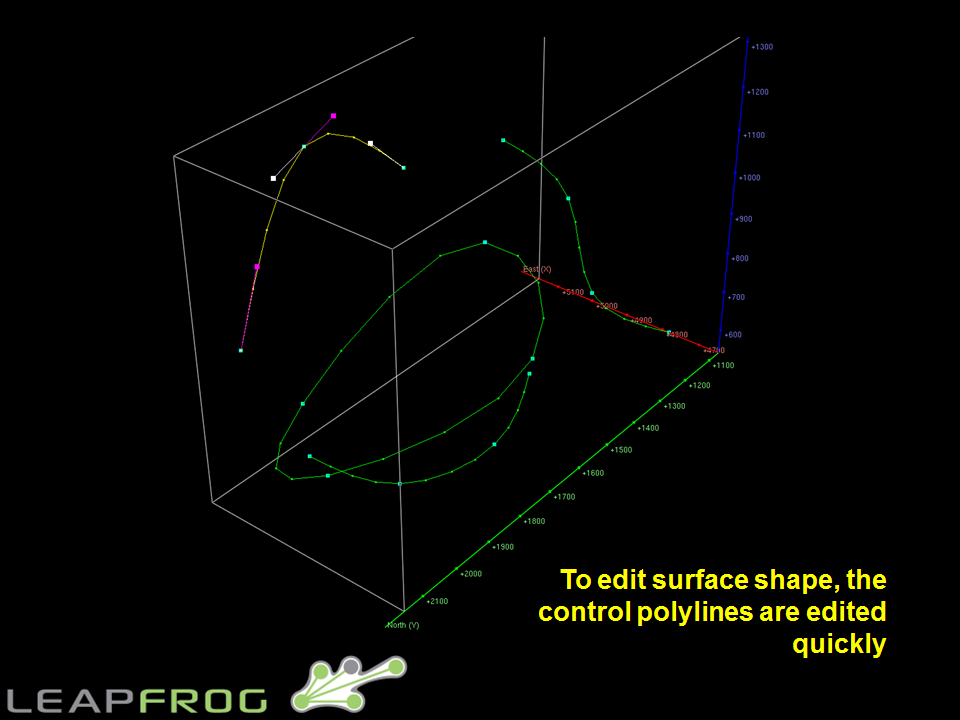

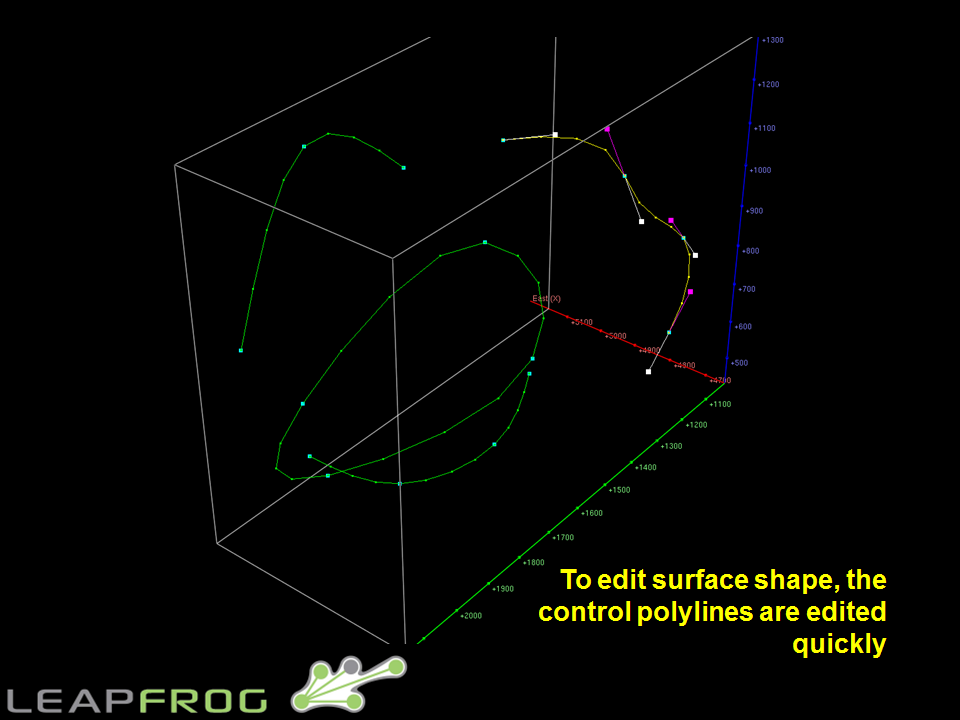

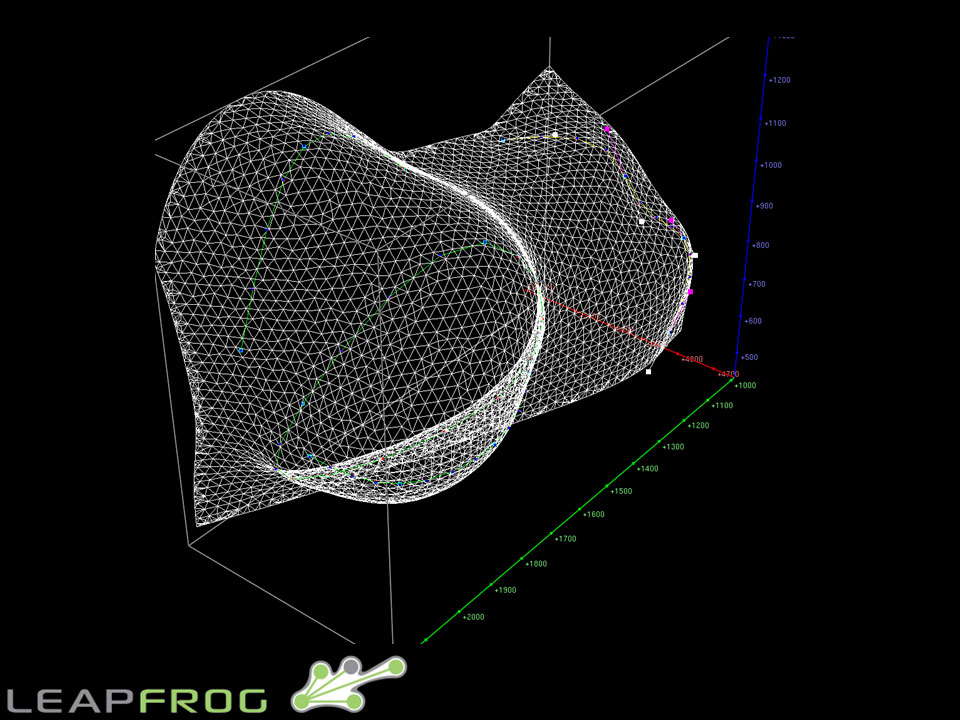

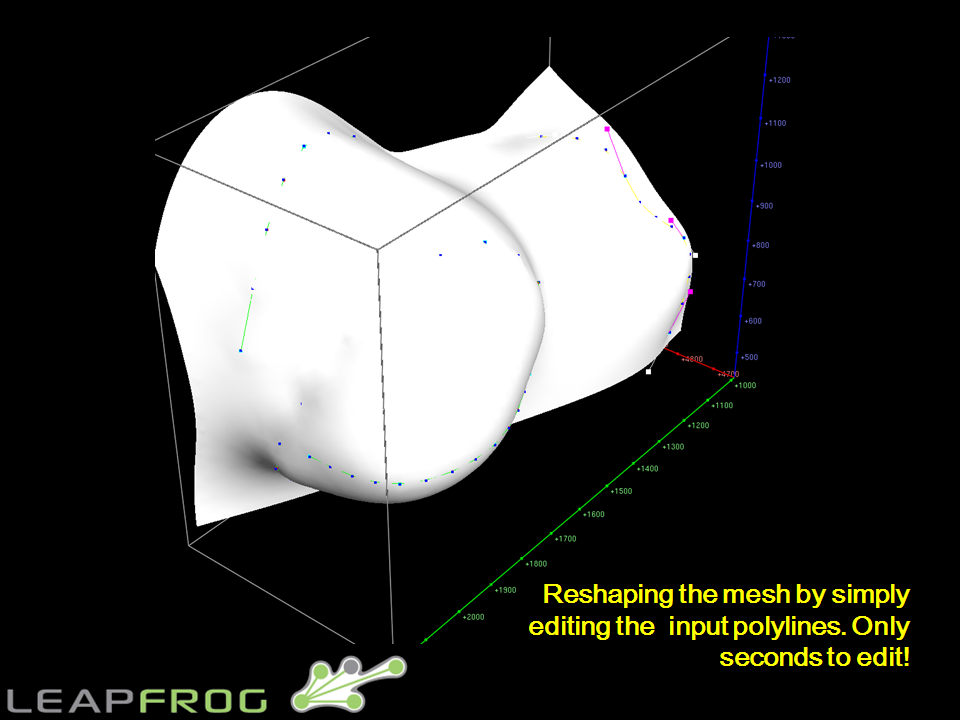

The very first demonstration images of the free-form drawing tool for Leapfrog featuring a simple Bézier curve drawing tool written by Dr Richard Lane. This Bézier tool inserted three points between the sparse control points, but it was good enough to produce smooth interpolated surfaces without artifacts. Drawing surfaces with RBF allowed users to manipulate the polylines easily and re-model, rather than manipulating the triangulation itself, which was a modelling approach taken by gOcad. Presented at an AIG conference in 2004, more than a decade ago.

The very first demonstration images of the free-form drawing tool for Leapfrog featuring a simple Bézier curve drawing tool written by Dr Richard Lane. This Bézier tool inserted three points between the sparse control points, but it was good enough to produce smooth interpolated surfaces without artifacts. Drawing surfaces with RBF allowed users to manipulate the polylines easily and re-model, rather than manipulating the triangulation itself, which was a modelling approach taken by gOcad. Presented at an AIG conference in 2004, more than a decade ago.

Ironically, the reaction of the audience proved to be correct—even after a decade, this drawing tool hasn’t gained a strong foothold in the industry. Other software companies—such as Micromine and MineSight—that have since developed implicit modelling software are still to release a product that works like Leapfrog’s drawing tool, so we were at least ten years ahead of any competition.

The original Leapfrog drawing tool - CAD and Bézier drawing modes rolled into one tool

Leapfrog’s original polyline drawing tool developed in 2004 had two distinct drawing modes. One way of drawing was identical to the drawing method that is implemented in all GMPs. This was by clicking the left mouse button for each control point and the polyline tool drew straight lines connecting the points (which I will refer to as the CAD-mode). In another mode, the drawing tool was designed as a Bézier drawing tool almost as good as those found in many 2D professional illustration programs such as Adobe Illustrator, Corel Draw, and

Inkscape. In fact, this dual method of drawing works just like Adobe Illustrator, which I had used since 1987, so I had 17 years’ experience using the Bezier tool by the time Leapfrog’s drawing tool was designed. In the Bézier drawing mode, instead of clicking on the node points, the user imagines the curved line to be drawn and draws the tangent to the curve that is to go through that point. The curves are generated between the control points; there is no need to draw too many points to generate very accurate curves.

After these curves are drawn, the Leapfrog program generates points along them and assigns them zero values. In addition, the program creates ‘off-surface points’ off the main lines with positive values on one side and negative values on the other. Once these numerical points are interpolated, the resulting 3D surface perfectly fits the Bézier curves. The biggest issue most people had with the 3D drawing tool was the Bézier method of drawing.

Drawing Bézier curves with tangents takes a bit of practice, but anyone can master it if they follow some simple rules.

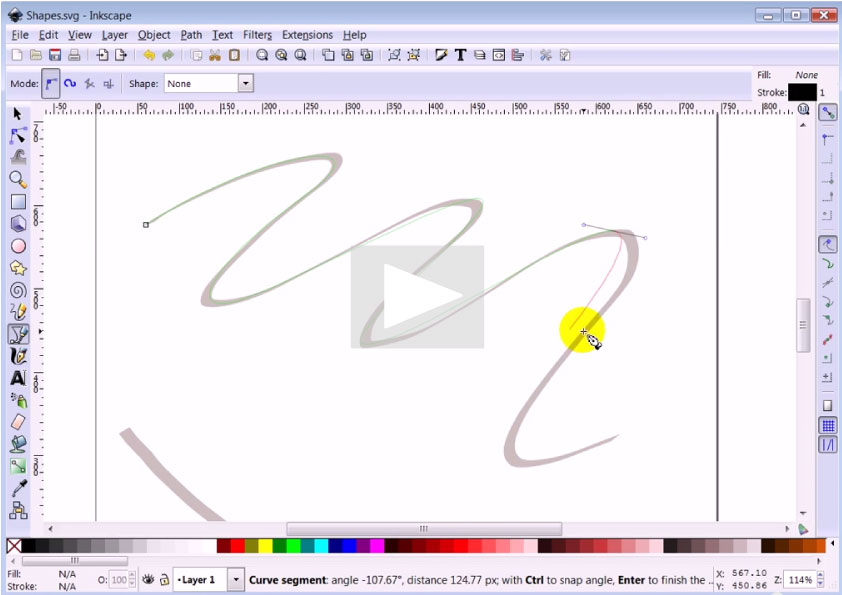

Below is a short video of me showing how to draw Bézier curves using Inkscape (click on image).

Click on the image to view the video demonstrating the use of Bézier drawing tool in Inkscape.

Click on the image to view the video demonstrating the use of Bézier drawing tool in Inkscape.

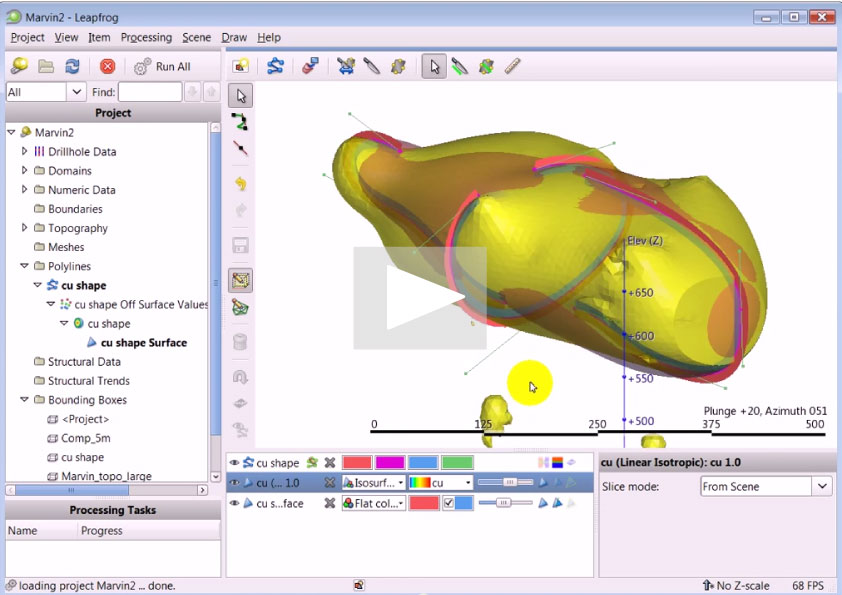

The second video (from 2009) shows me demonstrating how tracing an object can teach people how to get used to the Bézier drawing tool.

Demonstration of Leapfrog's original Bézier drawing tool by the author in 2009.

Demonstration of Leapfrog's original Bézier drawing tool by the author in 2009.

I was very aware that this mode of drawing was unfamiliar to most mining or exploration geologists, but I didn’t implement the Bézier tool just to be different. There were logical reasons why the Bézier method of drawing should be the default drawing method implemented in Leapfrog.

The first was based on structural geological reasoning.

By the time I knocked on the door of ARANZ in 2001, I had spent eight years using my own software to interpolate structural data (Cowan 1996). Virtually all deposits that I have examined were hosted in strained rocks and these rocks had behaved as a continuum of mass during deformation. Under such circumstances, the rock particles are smoothly connected to each along some scale, and smooth RBF interplants and Bézier curves were best at expressing these continuous geometries. Structural researcher Eric de Kemp (1999) was experimenting with Bézier tools to model geology in 3D, so our strategy in 2004 was appropriate and being able to quickly model surfaces on screen was well ahead of its time.

However, the mathematical reason for using the Bézier curves as a default drawing mode was even more convincing.

The simple mathematical reason was that RBF interpolation (RBF)—the interpolant used in Leapfrog—is a mathematical function, and can only fit along a smooth line. Because polylines consisting of points and straight lines are never smooth, a basic CAD-style drawing tool was inappropriate as a drawing tool for Leapfrog (illustrated below).

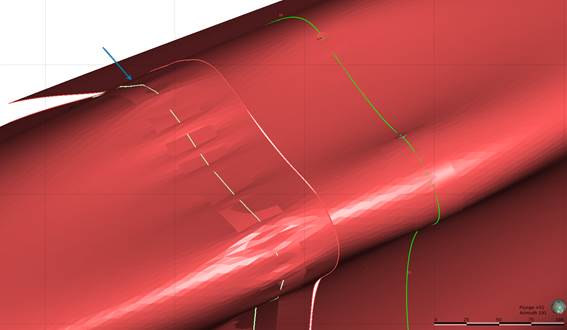

Leapfrog Geo (v. 2.1.2) with bumpy mesh artifacts along CAD-style polylines (LEFT). The recently re-introduced Bézier curves (29 Oct, 2013) do not have the same problem (RIGHT), but users were stuck with CAD-style polylines for 8 months. There was more than a six-year developmental lead-up to the release of Leapfrog Geo so it is clear that ARANZ Geo had no intention of putting the Bézier tool as an option until Leapfrog Mining users started to complain about the lack of the Bézier tool in Leapfrog Geo (v.1.2). As illustrated in this image, technically the Bézier curve tool wins hands down compared to the CAD-style polylines.

Leapfrog Geo (v. 2.1.2) with bumpy mesh artifacts along CAD-style polylines (LEFT). The recently re-introduced Bézier curves (29 Oct, 2013) do not have the same problem (RIGHT), but users were stuck with CAD-style polylines for 8 months. There was more than a six-year developmental lead-up to the release of Leapfrog Geo so it is clear that ARANZ Geo had no intention of putting the Bézier tool as an option until Leapfrog Mining users started to complain about the lack of the Bézier tool in Leapfrog Geo (v.1.2). As illustrated in this image, technically the Bézier curve tool wins hands down compared to the CAD-style polylines.

As long as there are sharp corners in the polylines, the smooth RBF function cannot fit these corners exactly. Of course, the line segments could be ignored and only the points used in the modelling, but that would be frustrating to use. Alternatively, the points have to be digitised very closely so that the polylines at a certain scale are viewed as being smoothly curved. There are two main ways to implement this in implicit modelling software:

- Draw a lot of closely spaced points as you would do in GMPs and develop repetitive strain injury (RSI) in the process, or

- Use Bézier curves so that the task can be accomplished in a fraction of the time with very few control points. Extra points along the smooth curves between the control points would simply be inserted by the software, thus avoiding RSI, as well as being a smarter way of using a computer.

Because of its speed and accuracy, I’ve been using Leapfrog Mining’s Bézier tool since it was developed by Richard Lane in 2004, and I have not stopped using it. However, most Leapfrog Mining users since 2004 were still using the CAD-style drawing mode, which created a problem because their expectations of modelling were based on a CAD-style GMP program and not based on a new modelling concept. The new modelling concept and Bézier curves were foreign to them.

Most users never framed their modelling assumptions and expectations to consider a completely new modelling concept that couldn’t model CAD-based jagged geometries.

The devolution of the Leapfrog drawing tool

For the first release version of Leapfrog Geo (v.1.4), the developers stripped out the Bézier curve drawing mode as well as the incredibly powerful geologically logical features of Leapfrog Mining, such as drawing Béziers directly on 3D objects by viewing down-plunge, and being able to reorientate the off-surface points. The Bézier tool was later added back into Leapfrog Geo v.1.4 eight months after the initial release of v.1.2, proudly trumpeted as a ‘NEW’ feature! However, the Bézier tool is now a completely separate drawing tool from the CAD-mode drawing tool, and it can only draw in sections and cannot draw on 3D objects (as of the current version of Leapfrog Geo v.2.1.2). The elegant all-in-one drawing tool from Leapfrog Mining is gone, and some of us are still wondering what benefits we have gained from this ‘upgrade’. The CAD-mode drawing tool was the default, and the only available drawing tool for Leapfrog Geo when it was released on 25 February 2013 and ARANZ Geo has promoted Leapfrog Geo as being far better than Leapfrog Mining; power users of Leapfrog Mining were underwhelmed and disappointed.

The CAD-style drawing tool in Leapfrog Geo would never work effectively with RBF, and, as discussed above, would involve more work to produce high-quality results—results that can be generated easily and quickly in Leapfrog Mining, which has been very effective at doing so for more than a decade.

So why did the developers of Leapfrog Geo make the CAD-mode drawing tool the default and completely ignore the Bézier tool for years before Leapfrog Geo was released (ie, 2007-2013 leading up to launch)? This was an innovative technology that had been proven to work for almost ten years. That’s because the relationship shown in Figure 1 changed in a critical way, which is the topic of the

Part 2 of this post.

*ARANZ is the parent company of ARANZ Geo who makes Leapfrog software products. ARANZ owns the FastRBF engine and that is licensed to ARANZ Geo to use in Leapfrog.

**Zaparo Ltd was the joint venture company between ARANZ and SRK Consulting Australia set up to market and sell Leapfrog. When SRK left the JV, ARANZ Geo was formed to replace Zaparo Ltd.

References

Cowan, E.J., 1996. Construction of computer-assisted objective foliation trajectories. In: Deformation of the Eastern Sudbury Basin. Ph.D. thesis, University of Toronto, pp. 366.

Cowan, E.J., Lane, R.G., Ross,H.J., 2004, Leapfrog's implicit drawing tool: a new way of drawing geological objects of any shape rapidly in 3D. In: Mining Geology 2004 Workshop (Eds M.J. Berry and M.L. Quigley), Australian Institute of Geoscientists Bulletin 41, p. 23-25.

Christensen, C.M., 1997, Innovator's Dilemma. Harvard Business Review Press.

de Kemp, E.A., 1999, Visualization of complex geological structures using 3-D Bézier construction tools. Computers & Geosciences. p. 581-597.